MOLDINO - Radius Mill TR4F type | JSR GROUP

Radius Mill TR4F type

The groundbreaking TR4F type, with cutting depth of 2 mm × 2 mm feed rate per tooth

Overcomes all major issues encountered in mold machining, thanks to TR4F’s three unique features

| POINT 1 | Even with interrupted cutting |

High chipping resistance

|

selection of close pitch type 4000 Type | |

|

||

| 1mm × 2mm | ||

| Cutting depth | Feed per tooth | |

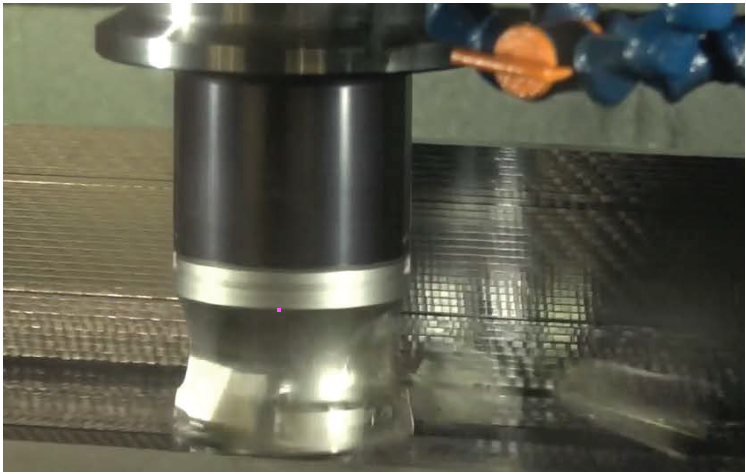

Tool performance that maximizes the machine’s full capabilities

Rugged cutting, regardless of load, thanks to the unique insert shape

【Cutting conditions】TR4F5000 type

Tool dia. :φ63 Cutting speed :vc=130m/min

Depth of cut :ap×ae=2.0×40mm

Work material :Pre-hardened steels (30HRC)

Machine:3-axis MC horizontal type(BT50,37kw)

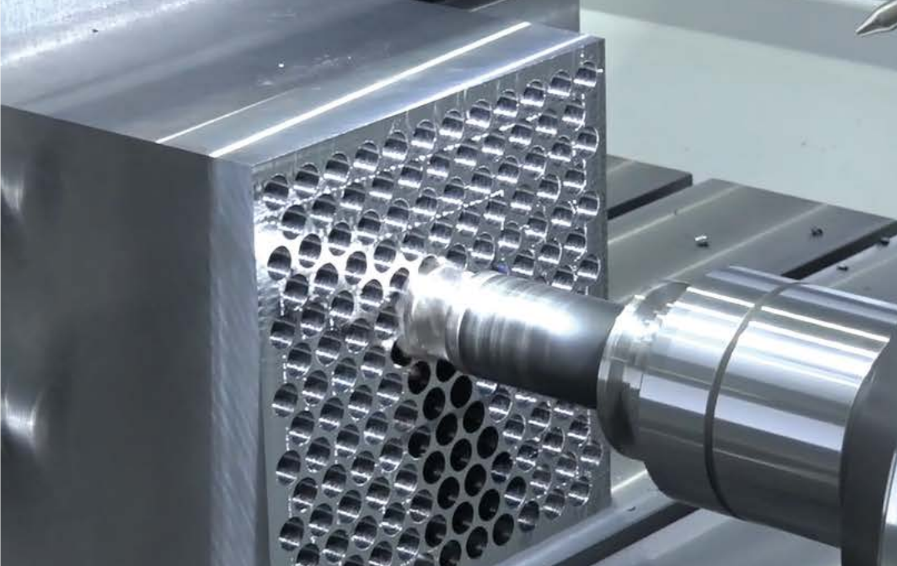

| POINT 2 | Even with wall face processing |

| Deep cutting 5000 Type |

Prevents scraping

|

|

|

||

| 2mm × 2mm | ||

| Cutting depth | Feed per tooth | |

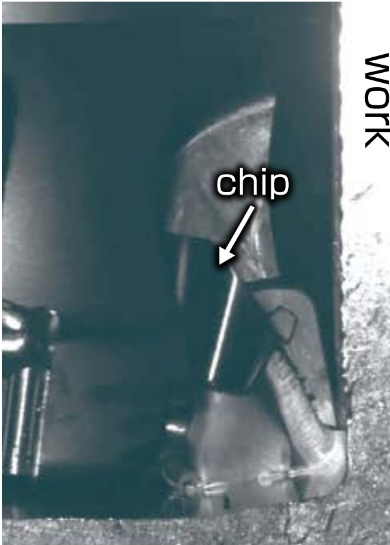

Chip ejection path away from work surface

Prevents scraping due to chip breakage and bending, which often occurs during wall face machining, whether cutting up or down.

|

|

【Cutting conditions】TR4F5000 type

Tool dia. :φ63 Cutting speed :vc=100m/min

Feed rate :fz=2.0mm/t Depth of cut :ap×ae=2.0×37.8mm

Work material :Pre-hardened steels (32HRC)

| POINT 3 | Even in chips |

Minimized biting risk

oughing technique achieves “super” high-feed cutting.

Exclusive high-efficiency cutting, resulting from unique insert and body shapes

TR4F type to meet specific challenges posed by high-efficiency cutting

| Issue 01 | Although high-feed cutting is performed for shaping, resulting severe chip clogging and biting may reduce shaping efficiency |

Proposed solutions

|

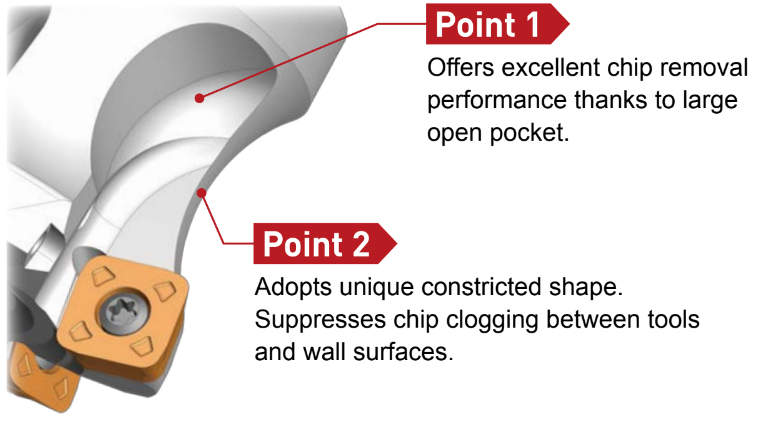

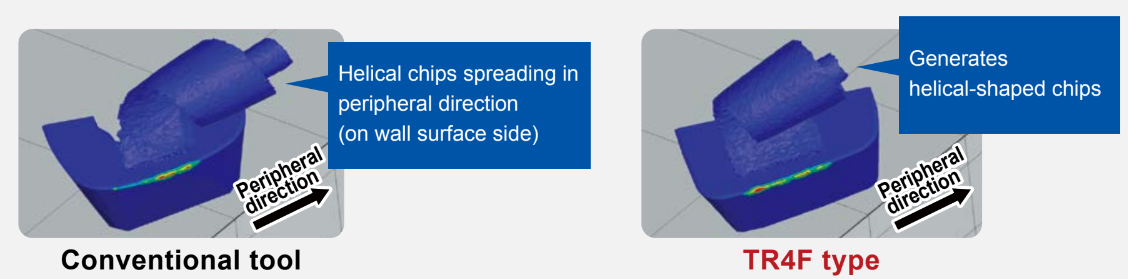

Adopts new body shape to enhance chip removal.

|

Generation of smooth twist-free chips

【Cutting conditions】 Tool dia.:φ63 |

| Point | Cutting edge designed to control chip flow |

Optimizes cutting edge design to achieve smooth chip removal flow; keeps chips away from wall surfaces.

Suppresses clogging from the time chip generation starts.

| Issue 02 | New equipment installed to improve the efficiency of the roughing process. The goal is to reduce machining times with high-feed cutting. But higher feed rates reduce tool life and keep the machine away from delivering its full potential. |

Proposed solutions

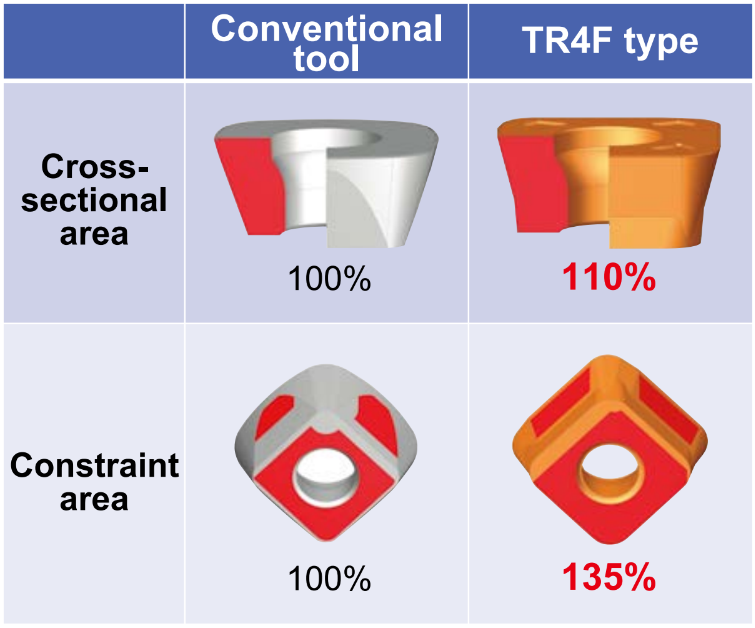

Developed a unique insert shape. Performs stable machining despite large cutting load generated during high-feed cutting with large cross-sectional and constraint areas.

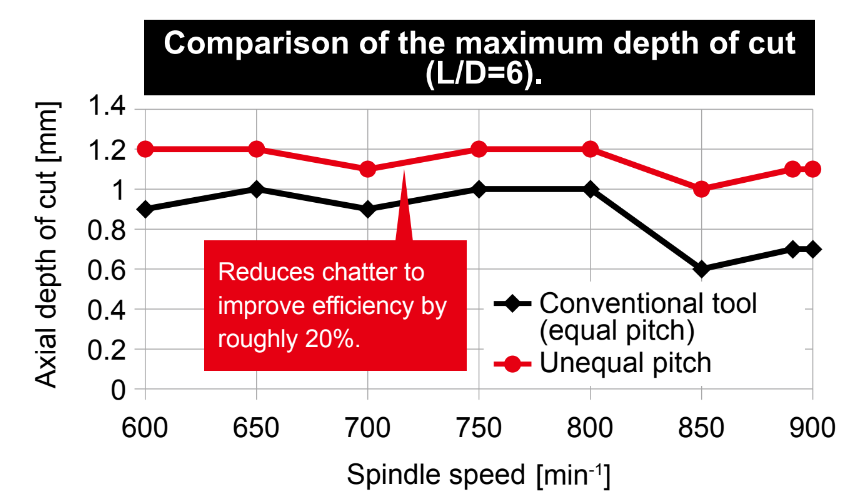

Adopts unique unequal pitch method to reduce chattering during cutting.

|

Secures insert strength and constraint force by enlarging cross-sectional and constraint areas even in high-load cutting. |

【Cutting conditions】 Tool dia.:φ50, No. of Flutes:4 Flutes, Unequal pitch reduces a vibration, a major factor of chattering. |

| Point | Meets the requirements of various applications and steel types. |

The unique cross-sectional shape and cutting edge design of a single insert meets the needs of a wide range of cutting mod

Diverse lineup of insert grades to meet the demands posed by a wide range of work materials.